Trevor Jarvis On Lug Cutting

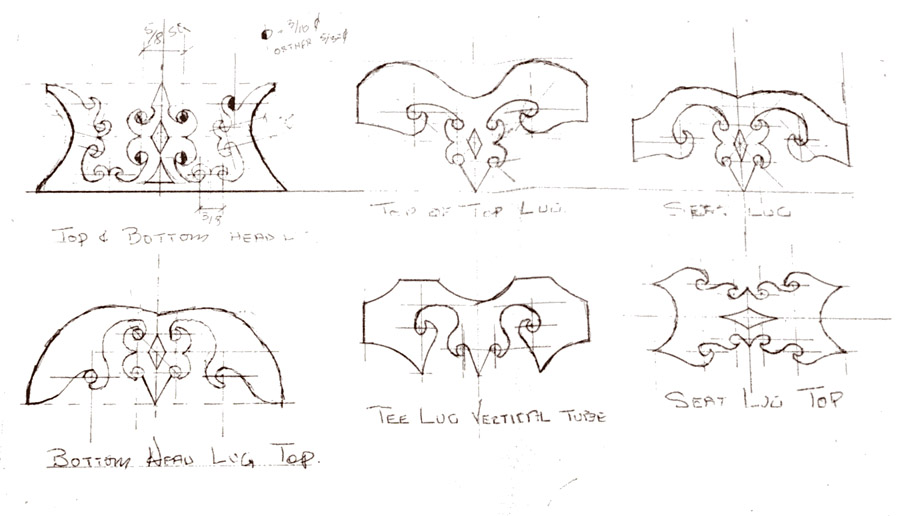

Trevor Jarvis demonstrated how a lug cutter might work out his designs and transfer them to lug stock.

First, he works a out complete design set on paper. (Below.)

|

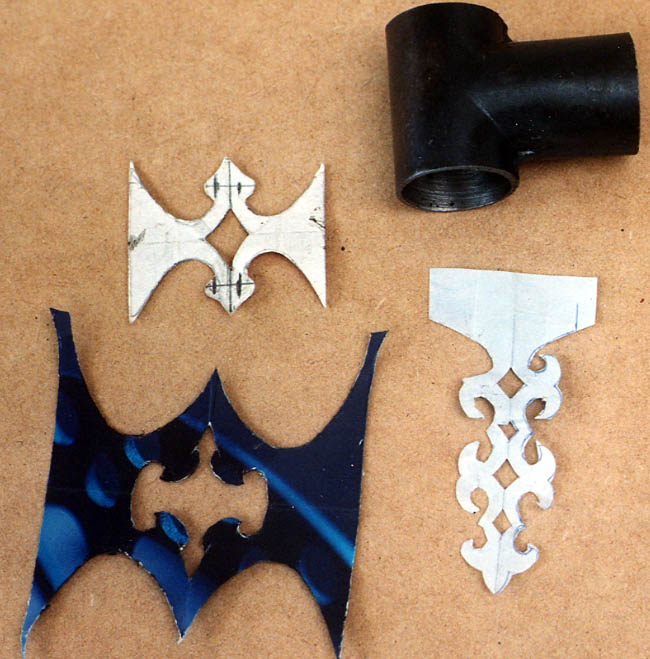

Next, the paper pattern is glued to lug stock and spray paint is applied. After the paper pattern is removed, a stencil is left over to be cut and filed away. (Below.) |

The lug blanks themselves may start out as castings or as pressed steel. If pressed steel, then these are stamped from flat stock and pressed round a mandril to produce the lug blank with two sockets. (Below, a piece of flat stock, half-way to being a lug blank.) |

(Below, paper pattern, pressed steel lug blank; the arrow shows the welded seam.) |

The same procedure is applied to flat stock for making embelishments, such as fork crown extensions and seat tube ornaments. Some lug cutters call these 'bi-laminations' or 'bi-lams.' Some frame builders fillet braze their frames and then add these bi-lams to the joints, a technique developed by Claud Butler.

|

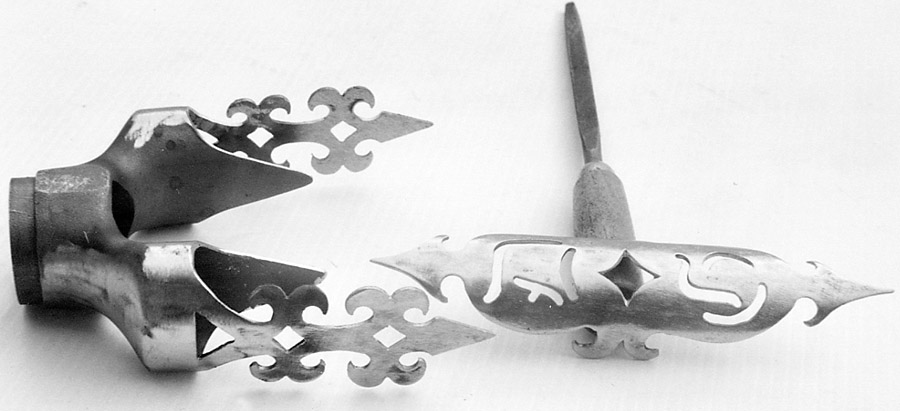

Below, one of Trevor's finished seat tube ornaments, showing the round saw blade necessary for such work.

Below, some samples of Trevor's work. What can't be shown, of course, are the hours of cutting, filing, drilling, and sawing which go into a hand-made lug set. |

Below is a foto of Trevor's workshop with a Gate on the jig. |

Trevor Jarvis' own Flying Gate